LyondellBasell Operational Excellence Audit

To maintain its world-class safety management system,

every four years PolyMirae invites LyondellBasell’s experts

in each field to conduct an audit on process safety and risk

management within the company, with self-audits such as PSM, ISO and RC.

These invitational audits involve a management system inspection,

on-site inspection and employee interview to identify risk factors

and potential improvements, and the degree of improvement

is tracked and managed through continued investment and actions.

Safety Inspection Day

At PolyMirae, employees with expertise in each field patrol

together with employees of the plant every second Tuesday

of the month to identify potential risks and improvements

in all fields including safety, health, environment and process.

Identified potential improvements are tracked and managed until completion.

Contractor Cooperation Program

To seek development in the safety and health working environment,

PolyMirae organizes a Contractor Cooperation Meeting with all its partners,

and holds monthly meetings to assess potential risks and actively engage

them in supportive activities to offset any identified risks.

CCG CAMPAIGN

CCG Campaign

PolyMirae staff report the progress and potential improvements

of all inspections, including internal/external safety inspections

and parent company inspections, to manufacturing director on

a monthly basis, and continuously tracks and manages the details.

Every LyondellBasell site around the world including joint

ventures holds an annual Global Safety Day event, to enhance

the safety awareness of employees and allow them to experience

the importance of safety as first priority.

PolyMirae management discuss HSE performance and initiatives

including investments related to safety with shareholders

every 6 months in an ad-hoc forum (HSE Committee).

To ensure safe operations, PolyMirae conducts sufficient on-site

practice and tests on employees to verify the work performance

of employees before assigning them new duties.

PolyMirae provides comprehensive medical testing and vaccinations

for all employees and their spouses in order to detect employee illnesses

in their early stages and assist in systematic employee health management,

so that employees can perform their duties with a good health condition.

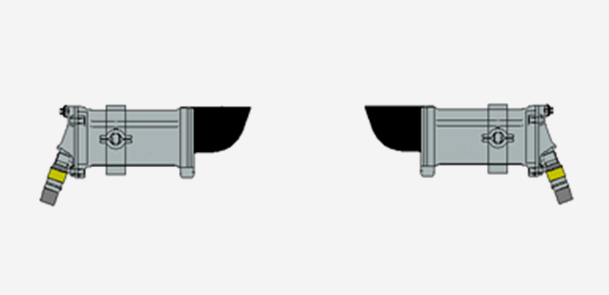

Remote Control Fire Extinguishing Facility

To extinguish fires early and prevent a major industrial accident

in the event of fire, PolyMirae has installed and operates a firefighting

monitoring system, which allows any outbreak of fire to be monitored

and quickly extinguished through remote control from the Control Building.

Spatial Infrared Gas Detector

PolyMirae has improved its gas leakage detectability and has introduced,

the first between in the Korea industry, the first spatial infrared gas detector.

In contrast to the generally used spot-type detector, which detects gas

only when the gas enters the sensor inside the detector, five newly-introduced

infrared detectors which are installed throughout the entire process detect

gas when the leaked gas enters 100~200m of space which the infrared beam passes through.

Control Building Clean Air Supply System

To protect employees in the event of a toxic gas leakage from

adjacent companies or a large-scale inflammable gas leak into the

process area, PolyMirae has installed a facility which blocks

polluted air from entering the Control Building, supplies clean air

and maintains positive pressure.

Process Area and Building Risk Assessment

PolyMirae has conducted a quantitative assessment of risks such as

leakage, fire or explosion on all facilities and buildings in the process

to secure employee safety in the event of an emergency, based

on which the company has invested in the installation of various facilities

and established emergency countermeasures to minimize damage

in the most severe accidents.

Water Spray Curtain System for Prevention of

Gas Diffusion

PolyMirae has installed and is operating a water spray curtain

system to prevent and suppress the diffusion of inflammable gas to

offices adjacent to the process in the event of a large-scale leak.

With a management philosophy that makes safety the top priority,

PolyMirae is investing actively in strengthening a culture of safety,

and applies a range of measures to improve and enhance the safety

environment to prevent industrial accidents and achieve a completely

accident-free business.

PolyMirae regularly and continuously conducts practical emergency response training to minimize human and material damage in emergencies such as earthquake / typhoon / heavy rainfall / warfare / major industrial accidents.

Companywide Emergency Response Training

The CEO, the company management team and all employees

including those in the headquarter participate in Company-wide

Emergency Response Training every year to train communication

and procedures, minimize damage and expedite normalization

in cases of emergency.

Disaster Response Team Training

PolyMirae runs a Disaster Response Team Training every quarter to

enable a swift and effective response and recovery from potential

accidents involving fire and explosion.

EMERGENCY

Firefighting Response Training

PolyMirae conducts joint fire drills with the fire station and

adjacent companies, as well as surprise firefighting

response drills that occur without notice.